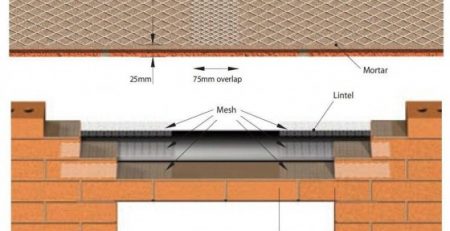

Perforated metal sheets for standard test sieves manufacture are usually produced by punching of carbon steel and stainless steel 304, 316, 316L, etc. Mostly used is round hole perforated metal plate.

Why Choose Perforated Plate Sieves Instead of Woven Wire Mesh Sieves?

The test sieves made of perforated sheets/plates enable improved productivity in many fields of operations: pharmaceutical, chemical, metallurgic, environmental and for special programs of chipping, control sifting (industrial sieves) and solid filtering.

How to Choose Round Hole Perforated Plate Sieves?

Compared with square hole and diamond hole perforated sheets, round hole perforated metal plates are the most commonly used sieving materials.

There are four technical factors for choosing the right round hole perforated plate sieves:

First, choose the right metal material: Carbon steel sieves or different grades of stainless steel. It depends on the work conditions and corrosion resistance property demand.

Second, Hole diameters: We have very small, medium and large size to meet various sizing requests.

Thirdly, Hole patterns: The most popular hole arrangement is the 60 degree angle pattern, which combines a high rigidity and a decent proportion between open and full areas . The 90° pattern is equally popular, above all for aesthetic needs whereas the 45° pattern is now almost disused.

Fourthly, the pitch distance or interaxis. This means the minimum distance between the centers of two adjacent holes. Whether you need standard pitch or custom pitch.